Views: 0 Author: Site Editor Publish Time: 2026-02-03 Origin: Site

Is your car shaking excessively while idling? Do you hear loud clunking noises when you accelerate or shift gears? These are classic signs that your engine mounting system might be failing. The engine mount plays a critical role in securing the engine to the chassis while dampening vibrations. When a car engine mount wears out, it compromises both comfort and safety.

Learning how to change engine mounts can save you significant labor costs, but it requires patience and the right tools. This guide will walk you through the process, ensuring you understand the importance of a proper engine support fixture and how to execute the replacement correctly.

Why does a small component like a car engine mount matter so much? The engine is a heavy, vibrating powerhouse. Without a functional engine mounting system, that power translates into harsh vibrations throughout the vehicle frame. A broken car engine mount allows the engine to move excessively. This movement can damage other components, such as radiator hoses, wiring harnesses, or even the exhaust system.

Replacing a worn engine mounting ensures your vehicle runs smoothly. It restores the structural integrity of the engine bay. Ignoring the problem often leads to more expensive repairs down the road. If you suspect an issue, checking the engine mounting condition should be your first step.

Before you begin, you must gather the necessary equipment. Attempting this job without an engine support fixture or proper lifting gear is dangerous.

You will need a specific set of tools to handle the heavy lifting and precise bolting required for this job.

Tool Category | Specific Item Needed | Purpose |

|---|---|---|

Lifting Gear | Engine Support Fixture | Holds the engine weight from above while mounts are removed. |

Lifting Gear | Floor Jack & Jack Stands | Safely lifts and secures the vehicle. |

Hand Tools | Socket Set (Deep & Shallow) | Removes mounting bolts (sizes vary by car). |

Hand Tools | Breaker Bar | Loosens stubborn, rusted bolts. |

Hand Tools | Torque Wrench | Tightens new bolts to manufacturer specs. |

Safety Gear | Eye Protection & Gloves | Protects against debris and pinched fingers. |

Lubricant | Penetrating Oil | Helps loosen seized hardware. |

Using an engine support fixture is often safer than using a jack under the oil pan, as it prevents damage to the pan itself. However, if you must use a jack, always place a block of wood between the jack and the engine.

How can you be sure the engine mounting is the culprit? Visual inspection is key. Look for cracked rubber on the car engine mount. If the rubber is separated from the metal, the mount is toast.

Another test involves a helper. Have someone shift the car from Drive to Reverse (with the brakes firmly applied) while you watch the engine. Does the engine lurch or jump significantly? Excessive movement confirms a bad car engine mount. Listen for clunking sounds during this test. If the engine mounting is collapsed, metal-on-metal contact will occur.

Safety is paramount when working with heavy machinery. How should you set up the car? Park on a level surface. Engage the parking brake firmly.

Next, disconnect the negative battery cable. This prevents accidental electrical shorts if your wrench touches the starter or alternator while working near the engine mounting. Lift the vehicle using the floor jack and secure it on jack stands. Never rely solely on a hydraulic jack. Once the car is secure, set up your engine support fixture. This bar goes across the engine bay, resting on the fender channels. Attach chains or hooks to the engine lifting points. Tighten the engine support fixture just enough to take the weight off the mounts. You aren't lifting the engine out; you are simply supporting it so the car engine mount can be removed.

Which mount should you start with? It is best to replace one engine mounting at a time. This keeps the engine aligned and safe. Locate the bolts securing the car engine mount to the engine block and the vehicle frame.

Apply penetrating oil to all bolts. Allow it to soak for at least 15 minutes. Use a breaker bar to loosen the bolts. Once loose, switch to a ratchet. If the bolt is spinning but not coming out, you may need to adjust the height of your engine support fixture slightly to relieve tension on the bolt.

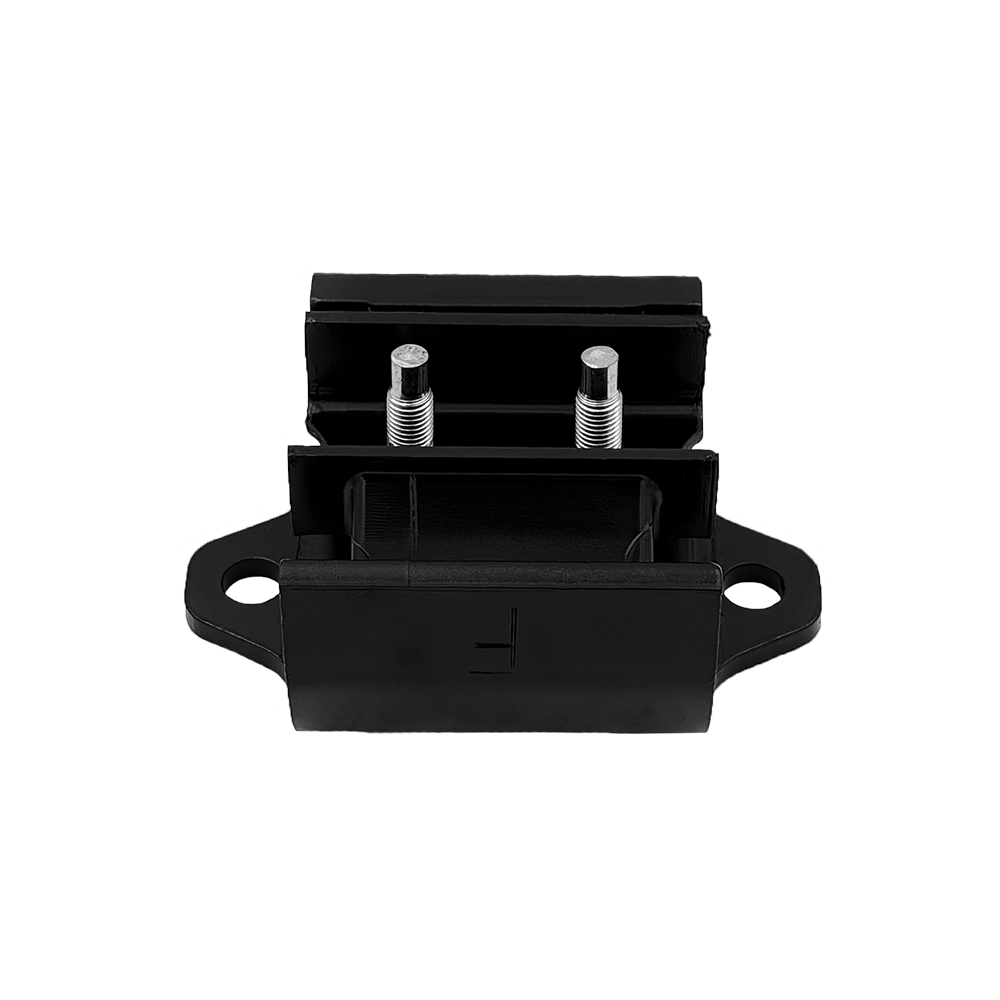

Carefully remove the old car engine mount. Compare it with your new part to ensure they are identical. A mismatched engine mounting will cause alignment headaches later.

Is there a specific technique for installation? Yes. Place the new car engine mount into position. Insert all bolts by hand first to avoid cross-threading. Do not tighten them down fully yet.

You may need to lower or raise the engine support fixture slightly to get the holes to line up perfectly. Once all bolts are threaded, torque them to the manufacturer's specifications. This step is crucial. Loose bolts can vibrate out, while overtightened bolts can strip the threads or crack the engine mounting bracket.

Repeat this process for each engine mounting that needs replacement. Remember to check the transmission mount as well, as it is part of the overall support system.

After all new mounts are installed and torqued, how do you finish up? Slowly lower the tension on the engine support fixture. Ensure the engine settles correctly onto the new car engine mount.

Remove the fixture from the engine bay. reconnect the battery. Lower the vehicle from the jack stands. Start the engine and let it idle. The excessive vibration should be gone. Take the car for a test drive to ensure the clunking noises have vanished.

Can you do this without a fixture? While some use a block of wood and a jack under the oil pan, an engine support fixture is the professional standard. Oil pans are often made of thin steel or aluminum. Supporting the entire weight of the engine on the pan can dent or crack it, leading to oil starvation.

An engine support fixture hangs the engine from the top, which is how the engine mounting system is designed to handle the weight. It provides a stable work environment. When you remove a car engine mount, the engine becomes unstable. The fixture keeps it exactly where it needs to be.

Do engine mounts last forever? No. Rubber degrades over time due to heat and oxidation. Most car engine mount components last between 60,000 and 100,000 miles. However, aggressive driving, oil leaks (which dissolve rubber), and harsh climates can shorten their life.

Include an engine mounting inspection in your regular maintenance routine. Every time you change your oil, take a quick look at the mounts. Early detection prevents the "domino effect" of one broken mount causing the others to fail due to increased stress.

What happens if you delay the repair? A broken engine mounting allows the engine to twist violently. This can pull on the throttle linkage (on older cars) or stress the driveshaft joints. In severe cases, the engine can shift enough to hit the radiator fan or hood.

Furthermore, the vibration from a bad car engine mount is uncomfortable for passengers. It makes the car feel old and unreliable. Replacing the engine mounting restores that "new car" smoothness.

Does the brand of the part matter? Absolutely. Cheap aftermarket mounts often use inferior rubber that is too hard (causing vibration) or too soft (failing quickly). You need a car engine mount that meets or exceeds OEM specifications.

For reliable performance, we recommend checking out Condragon Parts. They specialize in durable engine mounting solutions that withstand the rigors of daily driving. Whether you need a standard car engine mount or specialized hardware, Condragon Parts offers quality components to get your vehicle back on the road safely.

It depends on the vehicle. A simple upper engine mounting might take 30 minutes. A difficult rear or lower mount, requiring the removal of other parts, can take 2 to 4 hours. Using an engine support fixture can speed up the process by providing better access.

An engine support fixture is relatively affordable compared to the cost of a cracked oil pan. You can also rent them from many auto parts stores. It is a worthwhile investment for DIY mechanics dealing with engine mounting repairs.

Technically yes, but it is not recommended. Driving with a broken car engine mount risks damage to the transmission, axles, and exhaust. It is best to replace the engine mounting as soon as possible.

It is not strictly necessary, but it is highly recommended. If one car engine mount has failed due to age, the others are likely near the end of their life too. Changing them all restores the engine mounting system to factory condition.

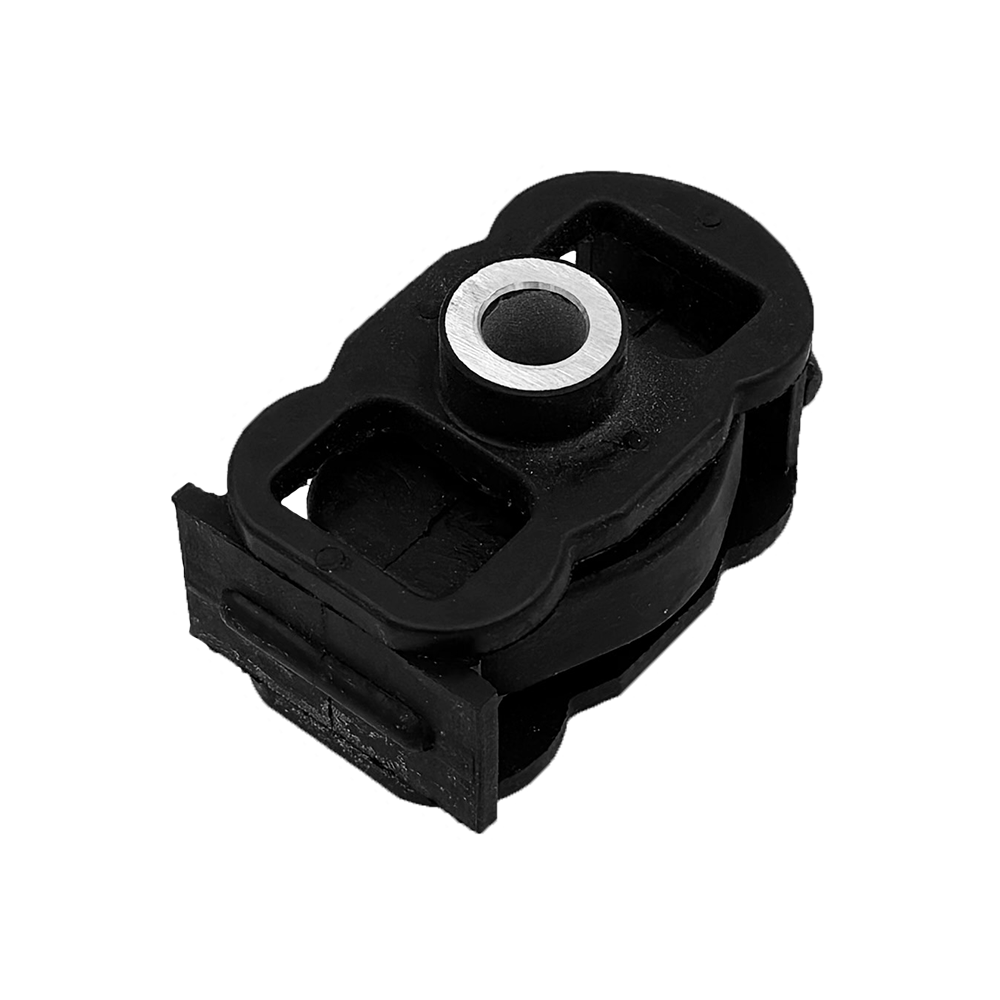

Consult your vehicle's manual. Many modern luxury cars use hydraulic (fluid-filled) mounts to dampen vibration better. If you see dark fluid leaking from the mount, it is a failed hydraulic engine mounting. Solid rubber mounts do not leak but will crack.

Yes. When you accelerate, the engine twists. A bad car engine mount allows excessive twist, which absorbs some of the energy meant for the wheels. It makes the throttle response feel sloppy.

For inquiries regarding premium engine parts:

Email: manager@condragonparts.com

Phone: +86 750 2859 838